- Home

- About Us

- Products

- Calibration

- Calibration of Mass Measurement Equipment – Weights, Electronic Scales.

- Calibration of Pressure Measurement System

- Capacity – Flow Calibration

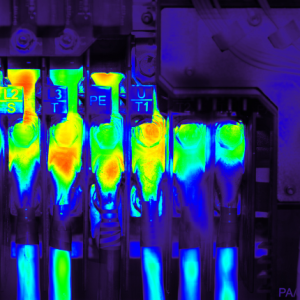

- Electrical – Electromagnetic Field Calibration

- Force Calibration – Precise, Reliable Hardness

- Length Calibration ensures measurement accuracy for measuring devices.

- Optical Calibration

- Physical and Chemical Calibration

- Sound – Vibration Calibration

- Temperature Calibration

- Time – Frequency Calibration.

- Services

- Recruitment

- News

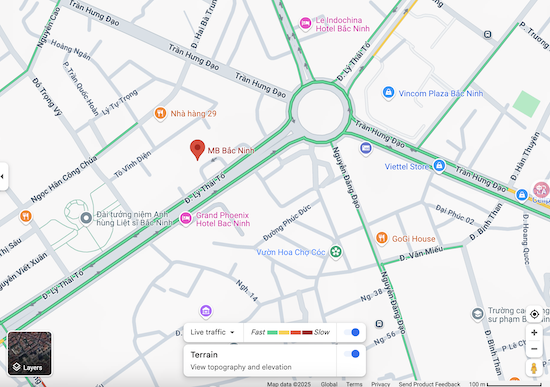

- Contact Us